how do mechanical trailer brakes work

How surge brakes work. Below are some tips to ensure the brakes are working correctly.

How Trailer Brakes Work How To Inspect Quick Short Tutorial Video Youtube

This air is then held in the air reservoir.

. Safety Features Most states require that trailers using electric brakes be equipped with a safety circuit called a breakaway system designed to apply the brakes if the trailer disconnects from the tow vehicle. Just so how do brakes work on a boat trailer. Surge brakes take advantage of this force to operate the trailer brakes.

In the electric trailer brake scenario if you apply the brakes on the tow vehicle the electrical current that is consequently flowing to the trailers drum brakes energises a magnet which applies. It is made to slide on a ledge into the back half of the neck. Mechanical override brakes use the tow coupling to manually pull a cable connected to the trailers brake drums.

As the car slows down the trailer brakes are operated by a piston in the drawbar. The tow ball in white exerts all the mechanical force from the towing vehicle onto the draw bar. With mechanical brake systems this means the cable between the over ride brake and the brake levers is required to increase in length accordingly the axle is moving away from the over ride coupling.

A master cylinder for the trailer brake is mounted on the back half of the neck and has a rod extending to the front half. The moment the driver applies the brakes the brake controller applies the same amount of braking power to the trailers brakes -- if the truck is stopping quickly the trailer will stop quickly. As the car brakes the coupling applies the trailer brakes.

Surge brakes are actuated with centrifugal force. The rear of the trailer relative to the trailer chassis. Mechanical brakes function via force delivered to a body in rotary or linear motion such as an axle shaft or wheel to slow or stop motion.

The front side with the hitch is separate and slides on the ledge to the back half of the neck. A brake controller is an electronic device that activates and as the word suggests controls the electric brakes of a trailer. When you step on the brake in your tow vehicle and slow down the trailer pushes against the hitch and presses a hydraulic cylinder.

It is a legal requirement that all trailers over 750kg GTM have operating brakes. How A Tractor Trailer Brake System Functions. If the truck stops slowly the trailer will.

When a trailer is designed to carry 3000 pounds it must have a working braking system. The compressor is a device situated on the engine that takes in and compresses air to be used in the pneumatic system. See the mechanical brake and clutch assemblies page for more specific data on these devices.

Proportional brake controllers use a motion-sensing device to detect how fast the tow vehicle is stopping. The coupling moves in and out of an overriding cylinder and in turn constricts the steel cables. Latch open Left The coupling latch should be open at all times when driving forward to allow the brakes to work.

When they are adjusted properly surge brakes are smooth and easy to work with. Some brake controllers have circuits that respond to the vehicles momentum while towing. There are electrical wires running from the trailer connector back to each brake on the axle as well as to the trailer lights to create a complete circuit.

How does a trailer brake controller work. When a trailer is being towed behind a vehicle and the towing vehicle applies the brakes the trailing vehicle continues to travel forward through centrifugal force relying on the tow vehicle to slow the forward motion. Also Know how long do.

An overriding coupling actuates the brakes. It uses electrical circuits and trailer gain settings to regulate the amount of braking power. A trailer brake controller uses electricity from the tow vehicle to apply a specific amount of power to the trailer brakes.

However in order to stop the trailer from going too fast in comparison to the car because of its weight the overrun brake exists. They are automatically applied by the brake controller and can be manually operated by a manual control which is installed within reach of the driver. A master cylinder for the brakes is mounted to the back half of the neck and has a rod extending from the master cylinder to the front half of the neck.

These are permitted when the GTM is under 2000kg. Compressing the front piston pulls a rod acctivating the drum brakes on each wheel. Mechanical overrun trailer brakes are also a relatively simple principle when a trailer is moving forward it moves with the speed of the vehicle.

A mechanical park brake activated via a lever and pin on the A-frame coupling typically augments the electrically activated system for drum brakes. Heres how it works. The more you slow down the vehicle the more pressure on the trailer brakes.

How do mechanical trailer brakes work. How Surge Brakes Work. In the drawing below shows the major components of an AL-KO over-run braking system.

Because the cable cannot actually extend what occurs is the cable starts to activate the trailer brakes instead. This in turn causes the braking shoes to contact the drum. However when you apply your brakes the trailer or caravan tries to continue at the same speed inertia and.

The front section with the hitch attachment is a separate piece. A brake controller can be roughly split in an interface positioned in the cab within the drivers reach and a main part responsible for activating the brakes of the trailer. An electrical connection on the trailer plugs into the connector on the vehicle.

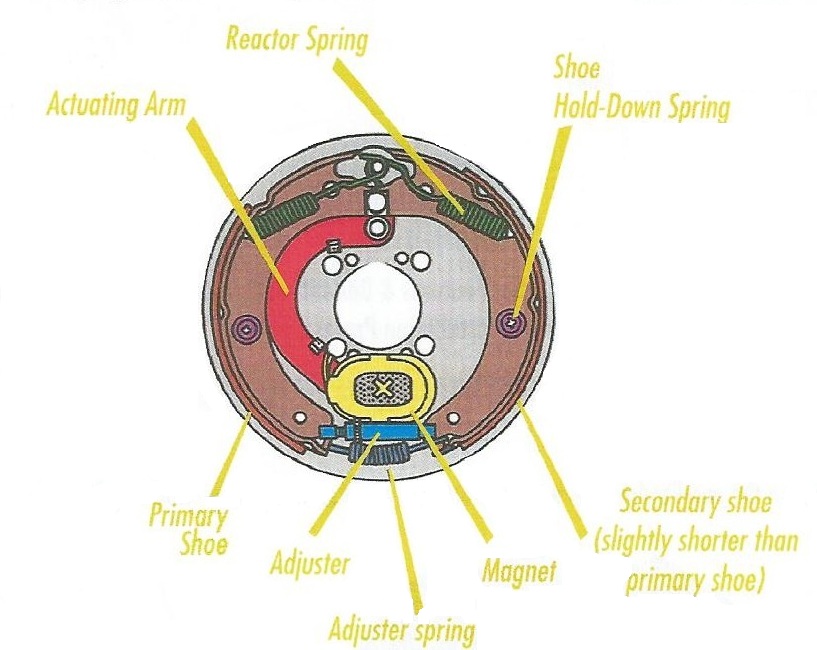

The neck of a trailer is two pieces. The rotating motion of the drum causes the actuating arm to pivot spreading the brake shoes causing them to come in contact with the brake drum and apply the brakes. When pulling the trailer or caravan forward the force is opposite to the arrows shown.

When the brake is applied the air then passes through the triple-valve system and air lines to the brake cylinder. These brakes mechanically move the actuator arm via steel cables which apply force to generate movement in the arm. The neck of the trailer is two pieces.

Mechanical brakes are often in an assembly with a mechanical clutch for engaging and disengaging shafts.

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

9 Trailer Mechanical Drum Brake Kit Coupling Fitting Kit 5 6 St Huntsmanproducts

Braking Guidelines Cm Trailer Parts New Zealand Trailer Parts Accessories Trailer Lights Boat Trailer Parts Trailer Wheels Tires Brake Systems For Trailers

Camper Trailer Brakes What Are The Options Expedition Australia

Trailer Brakes Options For Hunting Trailers Towing Quads And Buggies

Trailer Brakes Servicing And Maintenance Ilovefishing

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

How To Use Standard Trailer Brakes Adelaide Trailer Shop

How To Determine The Right Braking System For Your Boat Trailer Without A Hitch

How Al Ko Trailer Caravan Brakes Work Youtube

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

Torklift Central Surge Vs Electric Trailer Brakes Torklift Central Blogs

A Guide To Trailer Brakes Racq

Mechanical Brake And Rotor Trailer Axle Brakes Brakeassembly Tralierdrum Hub Brakedrum Brakecaliper Bo Brake Calipers Brakes And Rotors Boat Trailer

Trailer Brakes Electric Vs Mechanical Trailer Brakes A2b Trailers

Trailer Brakes Options For Hunting Trailers Towing Quads And Buggies

Why You Should Upgrade Your Trailer To Surge Brakes To Electric Brakes